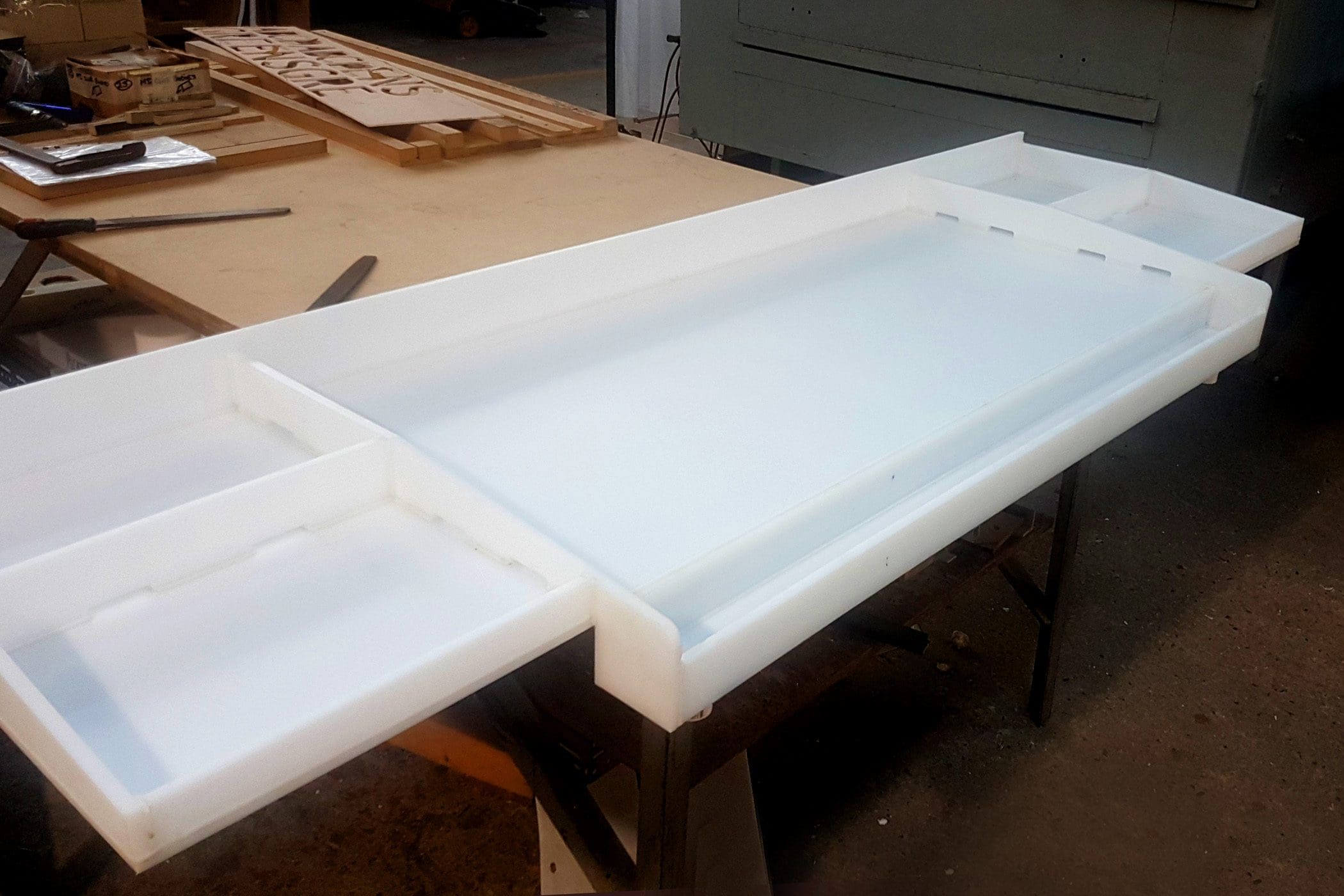

Custom marine parts, built for tough environments utilising tough materials.

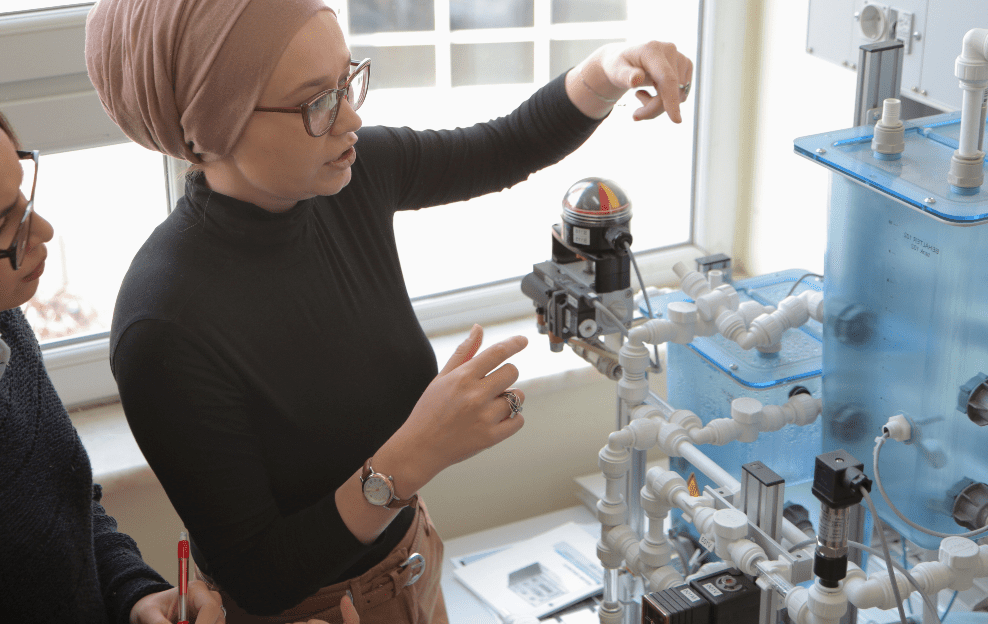

We have a team of experienced master craftsmen who utilise a wide range of machinery and techniques to get the job done, including thermoforming, infrared heating, vacuum forming, drape forming and edge finishing. From battery boxes to water tanks and bait boards, BCJ Plastic Products will spend the time to discuss your custom fabrication requirements and suggest the best method, material, and process to achieve your expected results.

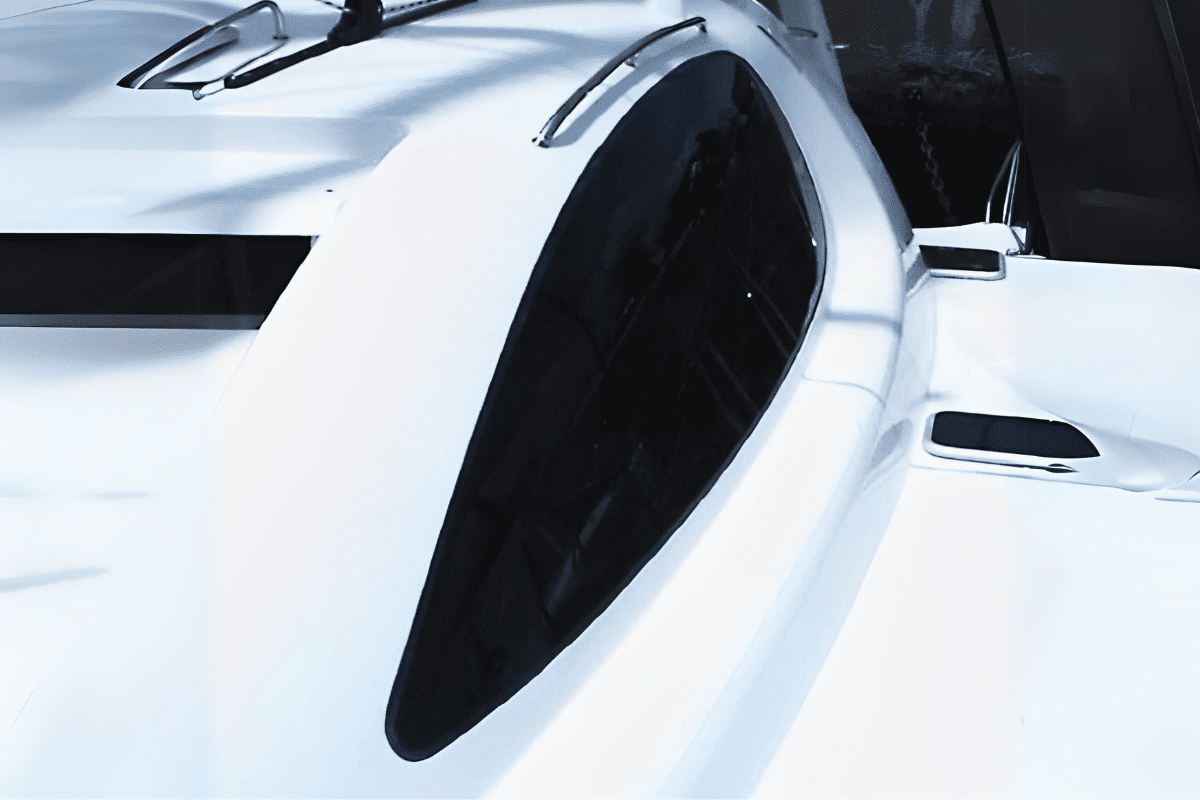

Whether you’ve got a speedboat or a luxury yacht, all vessels endure their fair share of wear and tear. Boat windscreens are no exception. As well as being exposed to harsh UV rays, boat windscreens in Perth also need to stand up to wind, water, and salt spray – not to mention the kids climbing over the top of it!

This is why manufacturing custom boat windscreens calls for specialty plastics. Our range of performance plastic options to replace your broken boat windscreen are tougher and safer than glass, and are designed to endure all the wear and tear the high seas can throw at them.

Do you need a custom boat windscreen or replacement part for your marine vessel? Get a quote online or call us on (08) 9353 3477.

Get a QuoteCustom Boat Windscreens

Our customised boat windscreens in Perth can be made in various shapes and sizes to fit any boat or vessel, and use high-quality materials designed for optimal performance in marine environments. Made from durable, shatterproof materials such as Acrylic or Polycarbonate and featuring customisable options such as tinting, UV protection. Our custom boat windscreens provide superior visibility and protection from the elements, ensuring a safe and comfortable boating experience.

Premium quality plastics paired with skilled master craftsmen

Working with premium quality plastics, our experienced master craftsmen employ a range of techniques to craft bespoke fabrications to endure tough maritime conditions. General materials used include;

- Polyethylene (PE): Resistant to corrosion, abrasion, and chemicals, PE is often used for marine applications like boat fenders and buoys.

- Polypropylene (PP): Known for its high strength and resistance to moisture, PP is used in various marine components, such as ropes, nets, and containers.

- Polyvinyl Chloride (PVC): PVC is used for marine upholstery, flooring, and piping due to its durability and resistance to water and chemicals.

- Acrylonitrile Butadiene Styrene (ABS): This thermoplastic is commonly used in marine applications, including boat interiors and components due to its strength and impact resistance.

- Nylon (Polyamide): Nylon is employed for various marine components like gears, bearings, and ropes due to its high strength, durability, and resistance to abrasion.

- High-Density Polyethylene (HDPE): HDPE is commonly used for marine structures, docks, and boat components due to its strength, durability, and resistance to corrosion.

- Acrylic (AC) or Polycarbonate (PC): AC and PC are employed for marine windows and transparent enclosures due to their high impact resistance and optical clarity.