Cast Acrylic

Cast Acrylic is a highly versatile and widely used product and comes in a range of sheets, high-impact sheets, rods and tubes. Extensively used for signs and displays, building and glazing, it is amongst the most scratch-resistant of all thermoplastics and its transparency, gloss and dimensional shape are virtually unaffected by exposure to the elements.

It has better thermal stability, higher resistance to crazing (when a network of very small cracks form) when exposed to solvents, wider thermoforming range than extruded acrylic. Cast acrylic has a better ability to be reworked hot and it is known for its superior surface finish and optical properties.

Cast acrylic is preferred over extruded in applications that require machining, such as turning on the Engine Lathe or milling/drilling. Extruded acrylic, with far less thermal stability, tends to melt and clog cutting tools. Even with slow speeds and lots of coolants, extruded acrylic does not produce the surface finish and tight tolerances achievable with cast acrylic.

Get a quote- Suitable for signage, display, food dispensers, safety windows and all manner of fabricated products.

- Excellent optical clarity & transparency.

- Highly resistant to variations in temperature, up to 17 times the impact resistance of ordinary glass, half the weight of glass, and ideal for precision machining.

- Highly resistant to many different chemicals.

- Acrylic (PMMA*) has certain properties making it an ideal material for use in a wide range of applications, including medical, life sciences and food/beverage testing.

*PMMA – PolyMethyl MethAcrylate. Crylux, Plexiglas, Acrylite, Lucite, and Perspex are trade names for Acrylic

- Relative Density 1.19 g/cm3

- Rockwell Hardness M 102

- Water Absorption -.2%

- Flammability Class 3, (BS 476 pt 7) UL94 HB

- Minimum Service Temperature -40⁰C

- Maximum Service Temperature 80⁰C

- Softening Point >110⁰C

- Linear Expansion 7.7×10-5

- Light Transmission > 92%

- Refractive Index 1.49

- Tensile Strength 75 MPa

- Flexural Strength 115 MPa

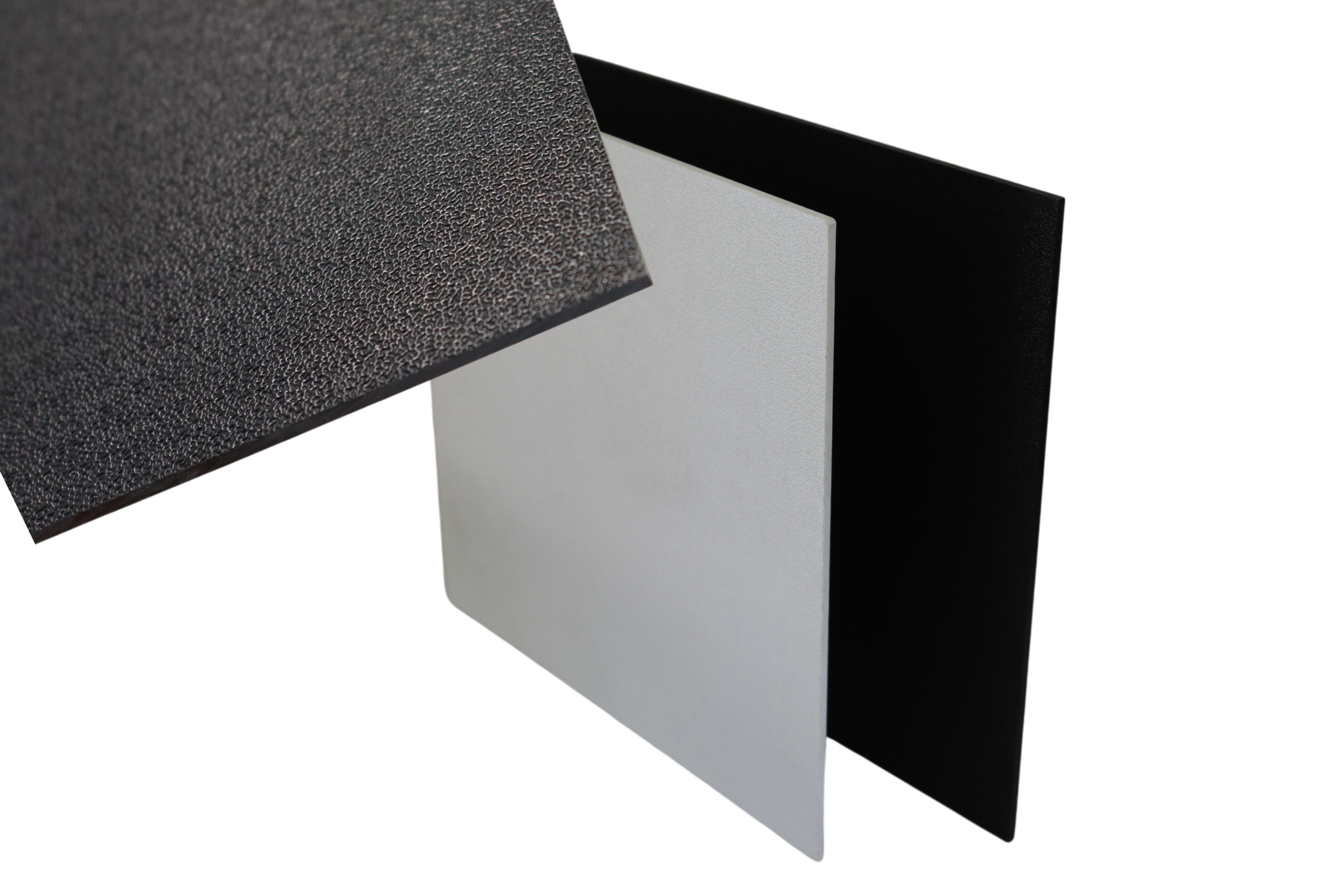

Clear, Opal, Black, Blue, Blue Tint, Brown, Bronze Tint, Flouro, Grey, Grey Tint, Green, Opal, Opal Ice, Orange, Red, Red Tint, Violet, Yellow, and White.

- Thickness varied from 1.5mm to 50mm (full range thickness only available in Clear)

- Standard size: 2440 x 1220

Can be purchased in full sheets OR we offer a cut-to-size service for Acrylic panel.