Nylon

Nylon is a strong, stiff engineering plastic with outstanding bearing and wear properties. Nylon is frequently used to replace metal bearings and bushings often eliminating the need for external lubrication. Other benefits include a reduction in part weight, less operating noise, and decreased wear on mating parts.

It has excellent tensile strength and can withstand significant stress without breaking or deforming, making it ideal for applications that require toughness and durability. Additionally, nylon has a high resistance to wear, abrasion, and impact, making it suitable for applications in harsh environments, such as machinery and equipment components.

Moreover, Nylon is available in different grades that can provide additional properties such as chemical resistance, heat resistance, and UV stability, allowing for further customisation to meet specific project requirements.

Get a quoteNylons are typically described according to numbers (6, 66, 11, 12, etc.) which relate to their molecular structures. Although there are many types of Nylon, the two most commonly available in sheet, rod, and tube are Nylon 6 and Nylon 6/6.

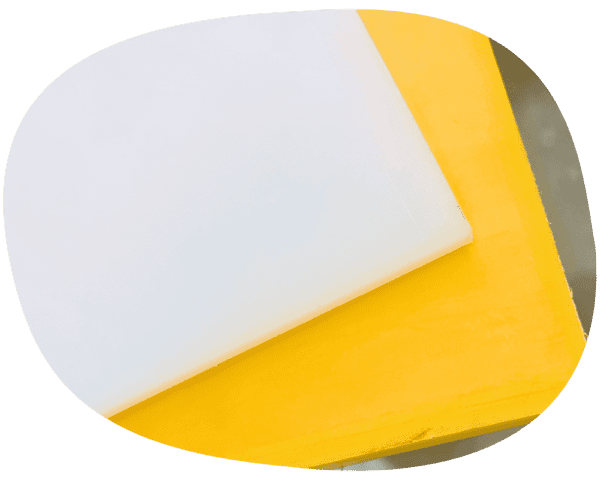

Nylon 6 and Nylon 6/6 – have very similar mechanical, thermal, and electrical properties. Both are available in a variety of colours and formulations that are engineered to meet specific application requirements.

Nylon 6 is generally manufactured into the sheet, rod, and tube via a liquid casting process. Casting is often the most cost-effective method for producing large-diameter rods, tubes, and thick sheets.

This process has the added advantage of allowing manufacturers to create custom near-net (irregular) shapes. Near net shapes are useful in the construction of parts that would yield poorly from standard sheet, rod, or tube stock.

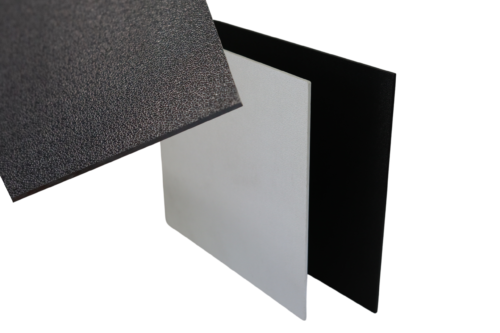

Nylon 6/6 sheets, rods, and tubes are usually produced by melting solid pellets of the polymer and processing them through a thermoplastic extruder. Extrusion is a fast and economical method for making small-diameter rods, tubes, and thin sheets.

Unlike cast Nylon 6 stock shapes, extruded Nylon 6/6 sheet, rod, and tubing can be manufactured to any length, which can be an advantage for cost-effectively yielding finished parts.

Nylon is available in a variety of specialty formulas.

- Molybdenum disulphide-filled (MOS2) and oil-filled nylons have enhanced wear properties often eliminating the need for external lubrication.

- Heat stabilised nylon withstands higher operating temperatures and for enhanced strength and stiffness, nylon is available in glass-filled grades.

- FDA compliant grades of nylon are available for direct food contact.

Nylon billets can be manufactured into many different components including gears, rollers, sprockets and augers. In power transmission applications, NYMETAL® billets combine the performance advantages of nylon and metal into one cohesive unit.