Polypropylene

Polypropylene (PP) is one of the most commonly used thermoplastics in the world. Polypropylene uses range from plastic packaging, plastic parts for machinery and equipment and even fibres and textiles. It is a rigid, semi-crystalline thermoplastic that was first polymerised in 1951 and is used widely today in a range of domestic and industrial applications.

Polypropylene has a slippery, tactile surface, making it ideal for plastic furniture and low-friction applications, such as gears in machinery and vehicles. It is highly resistant to chemical corrosion, making it an excellent choice for packaging for cleaning products and first-aid products.

It also offers excellent fatigue resistance and elasticity, securing it a well-deserved reputation for toughness and durability. In the automotive industry, polypropylene is used widely, for example in battery casings, trays and drink holders, bumpers, interior details, instrumental panels and door trims.

Finally, the medical world appreciates the waterproof properties of polypropylene too, as well as its flexible strength, resistance to mould, bacteria and chemical corrosion.

Get a quote- High-impact strength and toughness

- Printable (require correct grade)

- Die cuttable

- Weather resistant

- Light, Strong & Tough

- Resistant to grease and oil

A range of domestic and industrial applications.

- Colour: Grey

- 6, 10, 12, 15, 20, 25, 30mm thick – sheet size 3050 X 1500mm

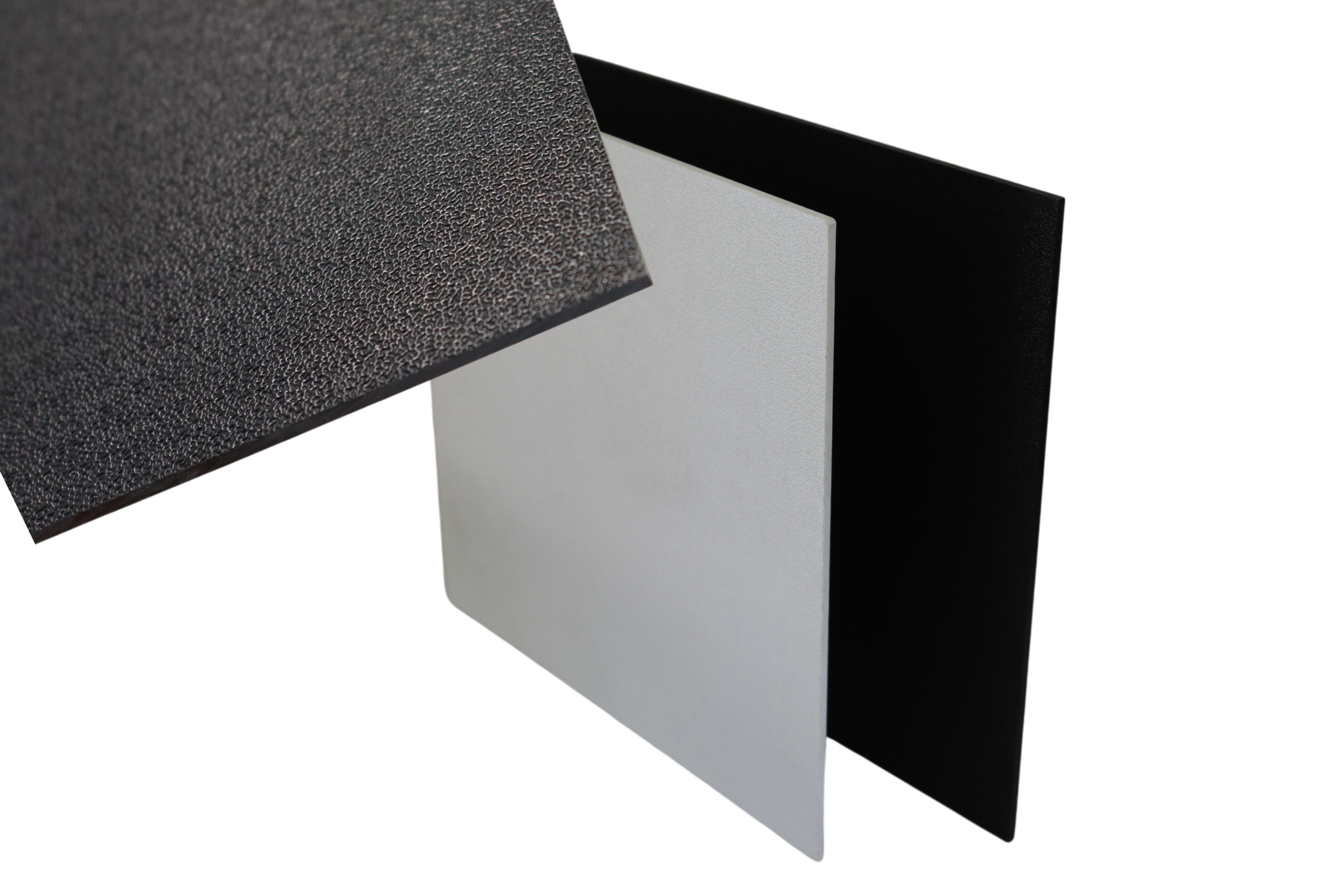

- Colour: Black, Sand White, Red

- 1.40 mm thick – sheet size 650 X 1360mm

Supplied in full sheets only and can be cut to size.