Plastic fabrication has been transformed by modern technology, allowing skilled professionals to manipulate materials like never before. Poly welding (aka plastic welding), in particular, has reimagined the way industries use rigid thermoplastics.

Similar to metal welding, poly welding uses heat to seal together two pieces of material. It’s used across a variety of industries, from mining and gas to commercial and retail.

Want to know more about poly welding? Read on to discover how poly welding is used in custom plastic fabrication in Perth at BCJ Plastic Products.

What is Poly Welding?

Poly welding is the art of fusing plastic surfaces together using heat, similar to how welding is used to fuse metals. Poly welding creates a strong and permanent bond. This makes poly welding a great solution for projects where strength and durability are key.

Types of Plastics Used in Poly Welding

Poly welding works particularly well with high-density polyethylene (HDPE). The polyethylene thermoplastic is manufactured from petroleum and reacts well to heat. This makes it easy to manipulate using poly welding. Other plastics suitable for poly welding include ABS, nylon and polycarbonate.

What is Extrusion Poly Welding?

At BCJ Plastic Products, poly welding is done using the extrusion welding process. Extrusion welding is carried out with a handheld tool that uses a bead of molten plastic to fuse materials. We specialise in two types of extrusion poly welding in Perth: freehand and speed tip.

Freehand welding

As the name suggests, freehand welding is done using a handheld tool. The tool emits a jet of hot air which hits the surface and weld rod tip simultaneously. This softens the rod and pushes it into the joint, fusing the parts together and creating a strong bond. Slow freehand welding offers considerable flexibility and can be used in a variety of different scenarios.

Speed tip welding

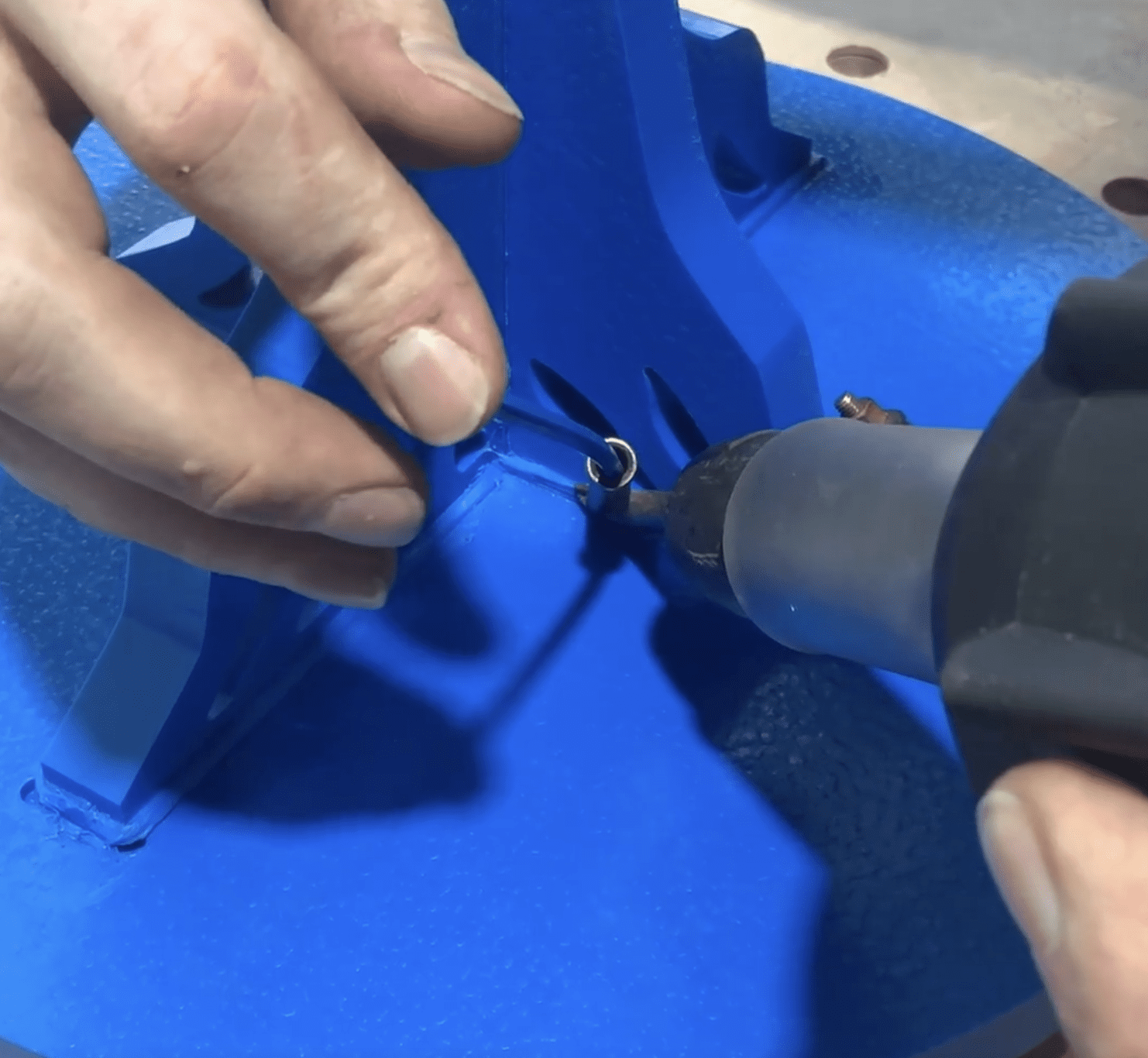

Faster and more efficient than freehand welding, speed tip plastic welding is great for use in tight corners and other hard-to-reach places. The welder resembles a soldering iron and features a plastic weld rod set in a feed tube. The speed tip simultaneously heats the rod and the substrate, which sets the rod in position and lays a bead of softened plastic into the joint.

Plastic Products Created from Poly Welding

Poly pipe welders are in high demand, often used in mine sites and commercial plastic fabrication workshops. In the BCJ workshop, you’ll find us using poly welding to create a huge variety of products, ranging from custom automotive, marine and caravan parts to retail displays and industrial parts.

Poly welding is also ideal for creative projects, such as this Blue Tree created in the BCJ workshop. First, a Machines Opticut oscillating knife system was used to cut the intricate shape out of a sheet of HDPE. Once this was done, speed poly welding was used to fuse the branches together and create a three-dimensional effect.

Are you looking for expert poly welding in Perth for your custom-made plastic products? Get a quote online or call us on (08) 9353 3477 to find out more about our high-end plastic materials and plastic welding techniques.