The industrial fabrication of materials has provided different items used for various applications in business and other aspects of life. One of these processes is acrylic fabrication.

In simple terms, the process involves the creation of different 3D objects through the transformation of acrylic plastics. The procedure utilises transparent plastic sheets, as the material provides top-tier stiffness, strength, durability and optical clarity.

Are you in need of a 3D plastic model for your business or require a specific acrylic exhibit for interior decor? You can count on BCJ Plastic Products to undertake the job and deliver on a timely basis. Contact us online for a quote.

How Does Acrylic Fabrication Work?

Acrylic fabrication is used in the production of different exhibits. This includes high-impact acrylic (HIA), such as lettering of corporate signage, coffee tables, cake stands, bookshelves and transparent TV tables.

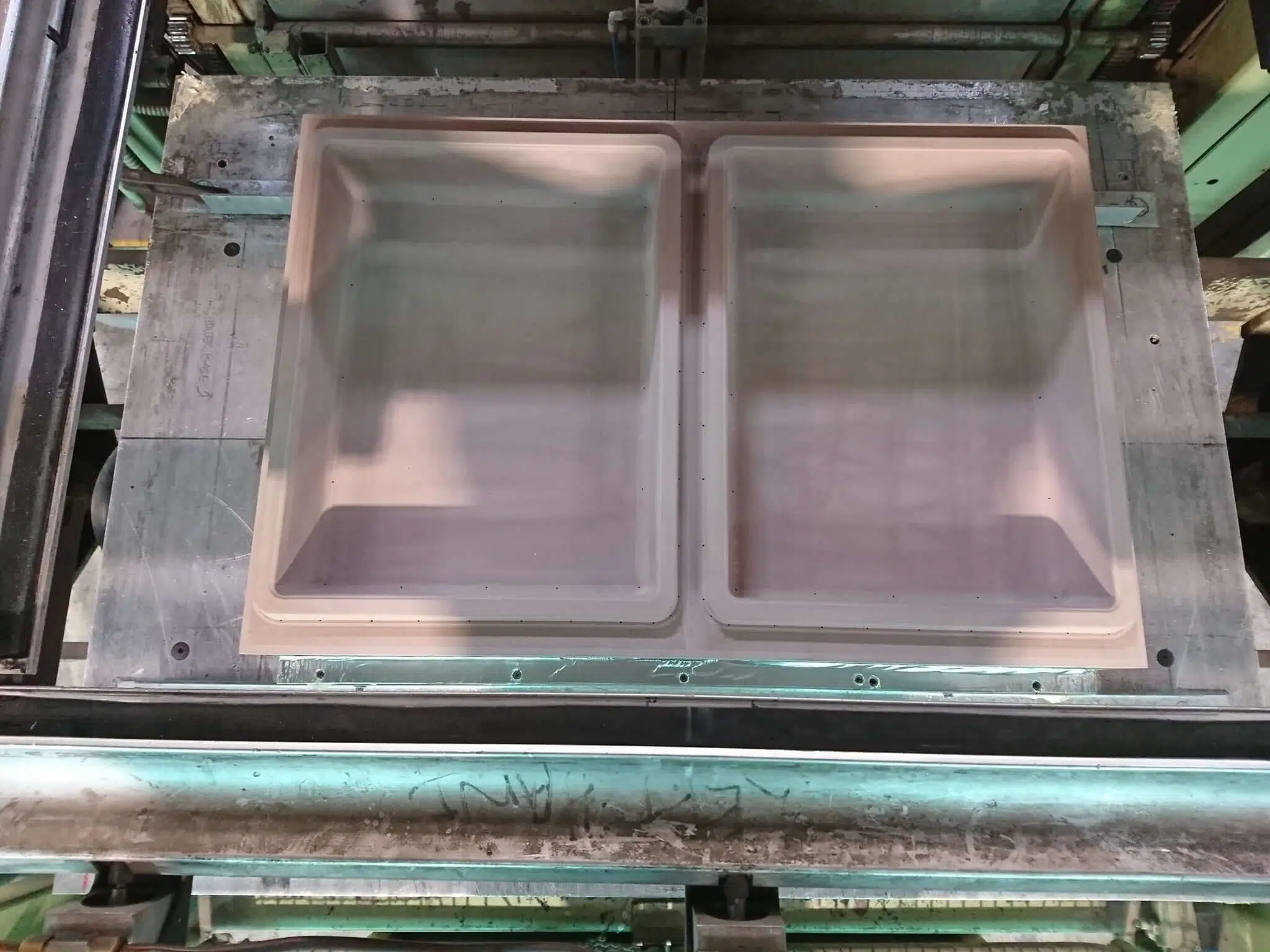

Due to the high malleability and availability of plastics, industrialists use the material to create versatile and long-lasting exhibits. However, getting the desired 3D models that involve intricate designs requires top-notch precision. That’s why most companies use the acrylic CNC cutting process that makes use of a CNC cutter.

A CNC cutting device is a piece of equipment that uses different size cutting tools to give it a precise and neat finish. The machine utilises computer software that operates on an X-and-Y axis and controls the speed and thickness of the cutter. The technology is widely used in acrylic precision because it is efficient and precise at cutting acrylic sheets.

Before you start the cutting process, you need to have a vector model of the intended model. Most fabricators use CAD (Computer-Aided Design) software to create single-line vector drawings. In such a setup, the CNC cutter can then cut the lines into the plastic sheets. Several CAD software options can be used in the creation of vector models, including Inkscape, Adobe Illustrator, AutoCAD and TurboCAD.

You should have a clear understanding of the software in use, particularly when dealing with coloured fabricates. Many CAD programs use an RGB (red, green and blue) colour scheme and millimetres. Thus, you need to indicate the colour of each line in the vector design and set the stroke depth of 0.01mm.

Where Do We Use Acrylic Fabrication?

Plexiglass or thermoplastic homopolymer, as acrylic is also known, is a suitable replacement for conventional glass material. The reason is that plastic can withstand high impact and provides some of the clearest fabricates in the market.

It was introduced in 1928 and was used in the creation of submarine periscopes used in World War I and in aircraft windows. Furthermore, injuries sustained from broken plastic are less severe than those caused by shards of shattered plastics.

In the modern age, acrylic fabrication is used in the creation of making plastic models used across various industries. This includes paints, acrylic nails, lenses, LCDs, security barriers and pieces of furniture.

Reputable fabrication brands use cast acrylic sheets in the modelling process instead of other alternatives produced through extrusion and lamination. That’s because they can be easily remodelled under heat and also deliver stand-alone clarity. That said, cast acrylic delivers highly when used as windows, displays in trade show exhibits, and tanks.

How BCJ Plastics Can Help with Acrylic Fabrication

While many acrylic fabrications companies deal with the production of a single design, BCJ Plastics is one of the leading brands in the plastic fabrication processes. We deal with a variety of acrylic exhibits, ranging from dispensers and acrylic mirrors to coffee tables, chairs and exhibition-display enclosures.

Whatever design ideas and specifications you have, we will work with you to ensure you get quality and affordable custom acrylic fabrication services. BCJ Plastic Products invests in technologically updated CNC laser cutting machines and a team of skilled designers and fabricators, making us capable of handling any project you have.